The Semiconductor Challenge: China Plays Catch Up with the West

High Noon for High Tech

The current plight of tech giant Huawei is indicative of the troubles large Chinese corporates may experience as they seek to augment their footprint and become global players. The poster boy of China’s technological prowess, Huawei Technologies’ corporate growth mirrored the country’s economic ascendancy: the Shenzhen-based company quintupled its revenue in barely ten years to around $90 billion (2017). Since mid-last year, Huawei churns out more smartphones than Apple. The company is expected to overtake Samsung in the next twelve months, becoming the world’s largest manufacturer of handsets.

Huawei’s almost exponential growth trajectory is all the more remarkable as no US mobile carriers offer the company’s smartphones to end-users. Because of security concerns, the US government has banned Huawei equipment from being used anywhere in the nation’s communication backbone. Japan, Australia, and New Zealand have placed similar restrictions on the use of the company’s hardware. Nonetheless, in 2016, Huawei overtook Sweden’s Ericsson as the world’s largest purveyor of mobile network infrastructure equipment, capturing a juicy 28% share of the global market.

Outgrown Copycat

Huawei Technologies has now largely outgrown its copycat phase – when it rather shamelessly misappropriated the designs of rivals to undercut their prices. Last year, the company spent close to $14 billion on research and development – an IT R&D outlay only topped by Amazon ($17.5 billion) and Google-parent Alphabet ($14.5 billion).

Early December, as it faced increased scrutiny after the arrest in Canada of CFO Meng Wanzhou, the daughter of the company’s secretive founder Ren Zhengfei, Huawei pledged to invest up to $2 billion in a major overhaul of its cybersecurity software and practices.

The greater part of Huawei’s product development cash has, however, been earmarked for next-generation G5 network technology – the frontier at which Chinese hardware manufacturers hope to wrestle control of the market from the still dominant Europeans. Today, Ericsson and Nokia can jointly claim a global market share of about 51% versus 41% for Huawei and ZTE.

This scenario represents much more than a mere competitive clash between corporate colossuses staking out claims in one of the most lucrative market segments. In fact, the recent trade spat that pitted the US and China against each other, and spooked markets around the world, may turn out to be only a dress rehearsal for a much larger confrontation.

Overdrive

The arrest of Ms Wanzhou (46), ordered by a New York district court over allegations that she may have helped her company circumvent US sanctions on Iran, is the opening shot that can turn a simmering cold tech war in a much hotter one. The Chinese Foreign ministry instantly went into overdrive, losing nearly all sense of proportion – and most of its decorum – whilst publicly dressing down Canadian ambassador John McCallum and calling Ms Wanzhou’s arrest at Vancouver International Airport ‘lawless, reasonless, ruthless, and extremely vicious’.

The ambassador was told in no uncertain terms to instruct his government to order the immediate release of Ms Wanzhou unless it was willing to suffer the consequences, which – Beijing assured – will be dire. The subtleties of the separation of powers is, unsurprisingly, lost on the Chinese government which remains largely ignorant of the concept.

That is precisely the bottleneck that China’s burgeoning tech sector must navigate and traverse in order to gain global acceptance, if not dominance. The country’s lack of mechanisms that ensure proper checks and balances – aka the rule of law – hampers its economic interactions with the developed world: China can only progress via subterfuge or bullying – and by doling out ready cash to any takers it can find.

Huawei’s smaller sibling, ZTE, was caught supplying technology acquired in the US to both North Korea and Iran via shell companies acting as intermediaries. Earlier this year, ZTE was sanctioned by the US Commerce Department which banned it from buying any US-made products – read: semiconductors – for seven years.

Seeing its global telecoms business crippled and with its very survival at stake, ZTE did what any corporate in a similar situation would do: it lawyered up and got out wads of cash to buy influence on the hill via lobbyists. The strategy worked wonders, especially after Chinese president Xi Jinping put in a personal appeal to his US counterpart. This mollified the Commerce Department which allowed ZTE to pay a one-off $1.4 billion penalty in lieu of the export ban.

The episode did, however, bring into full view the true balance of power: without ready-access to advanced US chips, China’s high-tech sector is powerless and quite unable to survive. Beijing is well aware of its vulnerability and has earmarked a significant part of the $150 billion Made in China 2025 investment drive, unveiled in 2014, for the development of a domestic semiconductor industry to close the technology gap – and break the US stranglehold.

Keeping China in Its Place

Amongst the world’s fifteen largest semiconductor manufacturers there is currently not a single Chinese company. The United States government has made no secret of its determination to keep it that way. Washington has either vetoed or discouraged Chinese companies from buying stakes in US semiconductor companies. It blocked the sale of Qualcomm to a Singapore-based firm, citing security and unfair competition concerns. It also imposed strict export controls on a smaller Chinese company, Fujian Jinhua, which Washington has accused of stealing technology.

Europe too is waking up, albeit slowly, to the threat posed by Chinese corporates buying its technological edge. The European Union is expected to launch a comprehensive framework to vet Chinese investments, especially those that include the forced transfer of technology – which is to say, most investments. According to a study compiled by PricewaterhouseCoopers (PwC) at the request of the European Commission and released (leaked) in April, over 94% of cyberattacks suffered by manufacturing companies in the EU seek to steal intellectual property and trade secrets. PwC researchers estimate that cyber espionage costs European businesses up to €60 billion in damages and forfeited economic growth.

This report was followed by a Bloomberg Businessweek investigation – ‘The Big Hack’ – into cyber theft that revealed the presence of tiny chips, the size of a grain of rice, implanted by Chinese subcontractors assembling circuit boards destined for servers assembled by a US company and sold to cloud services providers such as Amazon and Apple. Though Apple engineers reportedly detected the malicious chips in time and cancelled the company’s order for 30,000 Supermicro servers, the investigation concluded that infected hardware did find its way to almost thirty companies, including financial services providers and government contractors. The Chinese implants gave operatives backdoor access to most of the data hitting the compromised servers.

Even though China lacks a domestic semiconductor industry of note, its companies do manufacture most Western-designed hardware. Fully 90% of all PCs, and 75% of mobile phones, are made in China. Thus, a hardware hack was the obvious route to explore. Though all companies involved denied the Bloomberg story, the wire service stood by its reporters and even expanded The Big Hack coverage to include the news that a ‘major US telecom’ had all Supermicro servers quickly removed from its network after discovering security flaws.

Since the story broke, early October, Supermicro saw almost half of its market capitalisation evaporate. The company’s share price has only recently recouped some of the heavy losses incurred. Though drawing close to conspiracy-theory territory, the vehement denials, delivered in a near-perfect unison concert, can perhaps be explained by corporate, and governmental, reluctance to admit to a major security flaw involving the Chinese, preferring instead to address the issue promptly and exert greater caution in the future.

Wild Stories

The stakes are sufficiently high to invite wild stories. However, fact remains that semiconductors are becoming significantly more important to global trade patterns than old-school commodities such as steel and big ticket items such as automobiles. Though important, no doubt, these are not the products that will drive future growth and underpin global prosperity.

The global semiconductor industry – the one in which China has for the moment no noticeable presence – is currently worth an estimated $420 billion and growing at an annual rate exceeding twenty percent. Keeping up or accelerating that pace will see semiconductors overtake steel in the next six years or so to become one of the world’s most important industries.

Thus it becomes understandable why China is determined to secure a seat at this particular table, sparing no effort to stay off the menu. Policies to delay or thwart the country’s progress seem, however, destined for failure. In response to a US export ban on advanced Intel chips, China developed its own quasi-superchip and build the TaihuLight, a 93 petaflop device which between June 2016 and June 2018 claimed the top spot amongst the world’s fastest supercomputers. It has since been relegated to third place.

The TaihuLight employs 40,960 locally-designed and manufactured Sunway RISC processors, each containing 256 cores. China’s National Supercomputing Center in Tianjin is now building an exascale computer, capable of executing a quintillion (1018) or more calculations per second, which is expected to enter into service next year.

Whilst its efforts and achievements in supercomputing are impressive, on a more down-to-earth level Chinese chipmakers struggle to keep up with manufacturing technology which has now moved into the 7-nanometre node. The Kirin 980, the first commercially available 7-nm chip launched last September, is being used by Huawei in its top-of-the-line smartphones. The company sources these chips from a foundry in Taiwan – one of only five chip suppliers in the world driving the leading edge of semiconductor manufacturing. Another of China’s challenges is that currently only one company in the world – Dutch ASML – has mastered the extreme ultraviolet lithography technology that is employed in 7-nm chip-making machines.

New Frontiers

It is at this frontier that trade spats and wars will unfold. Whilst China has little chance of overtaking the West in high-end commercial chip design and manufacturing, the country’s policymakers and strategists do have an ace up their sleeve: 7-nm node technology is running up against physical barriers.

The benefits in processing speed of cramming ever-more transistors into ever-tinier packages are fast diminishing, meaning that the gargantuan effort needed to move from 10-nm to 7-nm technology does not provide a commensurate boost in speed. A thorough rethink of chip technology is now called for. Quantum computing or the use of super-specialised silicon are the future. These new frontiers, far removed from legacy chipmaking processes, offer China a chance to get in on the ground floor of their development – and provide shortcut to catch up with the West.

Whilst steel and automobiles grab the headlines as trading powers jostle for market share, the semiconductors industry is where the real fight for supremacy will take place. No big country or bloc can afford to lose this race.

The present travails of Huawei, and China’s over-the-top reaction to the arrest of that company’s CFO, is merely the latest manifestation of a much larger conflagration brewing in the wings. The future belongs to whomever powers it. China realises this as much as the United States and the European Union do. The stakes couldn’t, in fact, be higher.

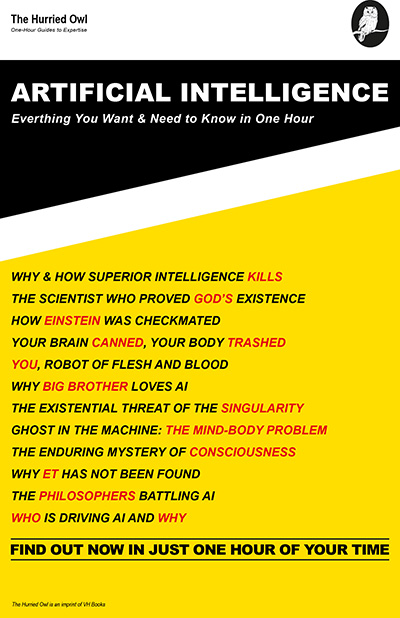

Cover photo: Plenty of workers, no automation needed. Thousands of workers assembling and testing electronics at a factory in China.

© 2005 Photo by Steve Jurvetson